Water Softener (Water Softening Plant), Water Softening Plant, Water Softener Systems, Water Softener Plant Manufacturer

Water and Process Solutions / Water Softener (Water Softening plant)

Water Softeners are used to remove the dissolved hardness minerals - calcium and magnesium - from water.

Calcium and magnesium are inversely soluble with water temperature. That is, calcium and magnesium precipitate out of the water as the temperature rises. Another way to say this is that water can hold less calcium and magnesium in solution as the temperature increases.

Inverse solubility becomes very important when you heat water in a boiler. The temperature at the boiler tube surface is so high that the calcium and magnesium plate out and produce very hard and difficult to remove scale on the surface of the tube. This scale is also insulating and makes the boiler less efficient wasting energy. This scale ultimately causes corrosion because of the excess heat and reduced circulation at the tube surface.

As a result, in almost all boiler water, water softeners are used to remove the hardness minerals - calcium and magnesium - from the feed water.

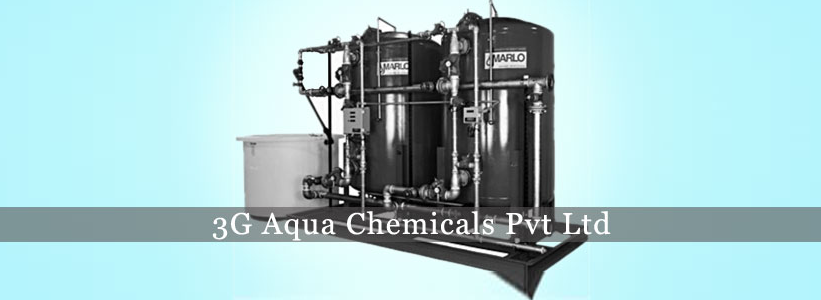

The Industrial Softeners is a manually operated ion exchange unit designed specially for industrial use. It is simple to operate, inexpensive to maintain and is widely used in the industry. The softener comprises Steel /FRP pressure vessels containing a bed of cation exchange resin, a regenerating system and control valves.

A strongly acidic cation exchange resin in sodium form is used to exchange sodium ions for the hardness –forming calcium and magnesium ions, and thus produce soft water. At the end of each service cycle, the ion exchange resin is regenerated with sodium chloride solution, after which the units is ready for the next service cycle.

For larger plants, a brine measuring tank is provided, and a separate salt saturator, preferably in concrete, is recommended for bulk storage of salt and preparation of brine.

Standard equipments is available to soften water, upto a maximum flow rate of 275m3/h.